Frontiers Optimizing a FedBatch HighDensity Fermentation Process for Medium ChainLength

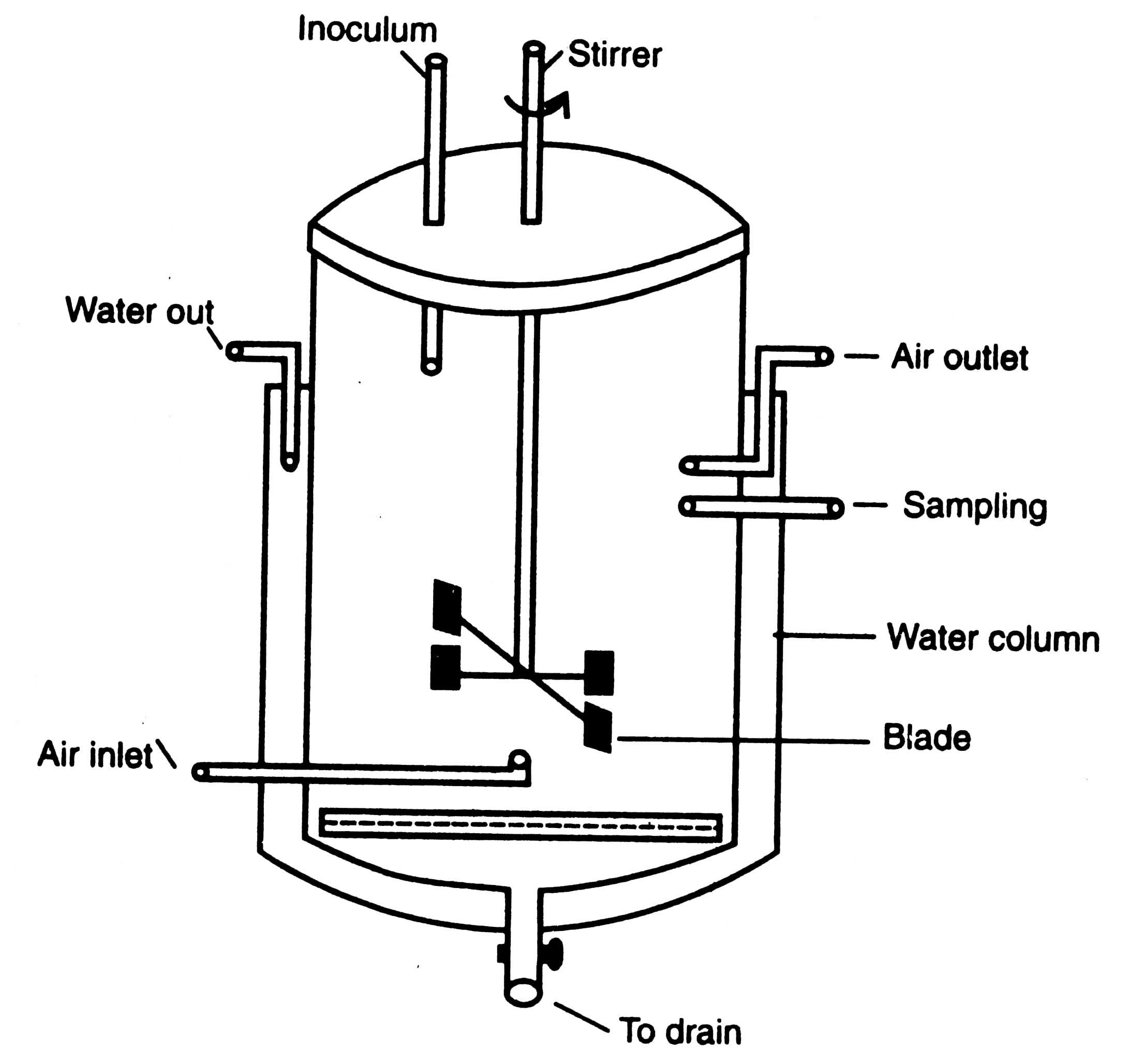

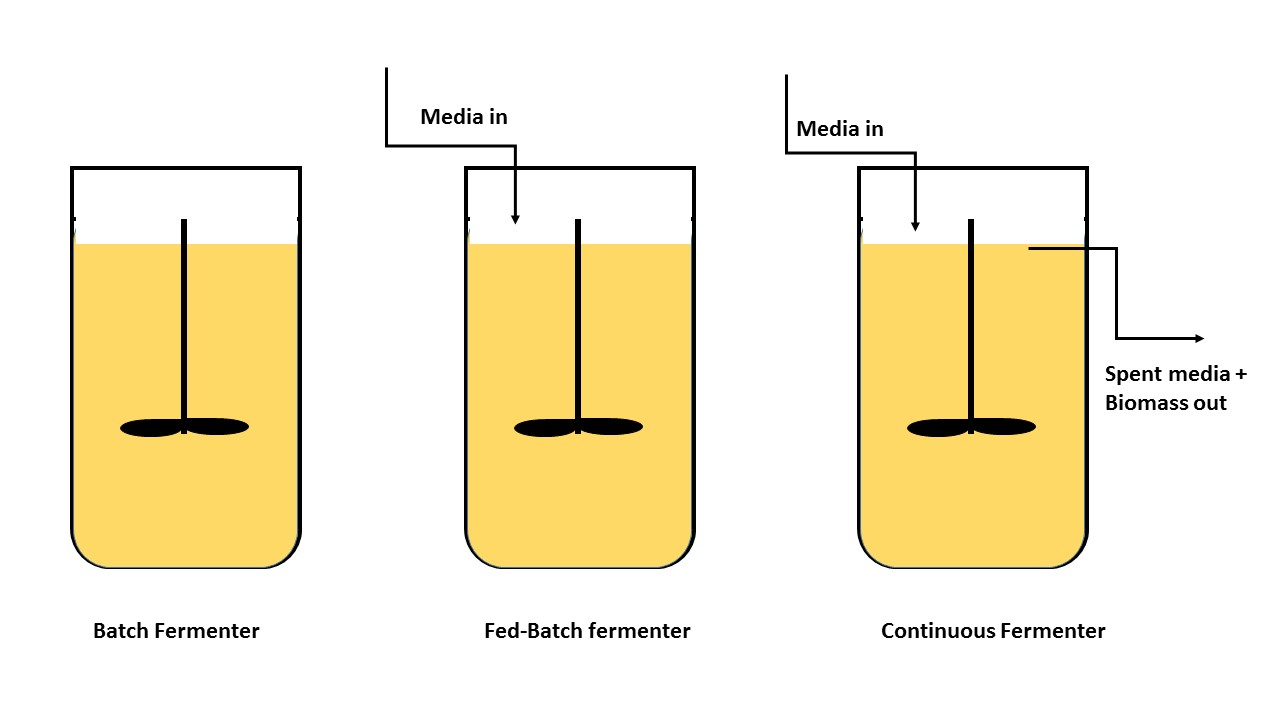

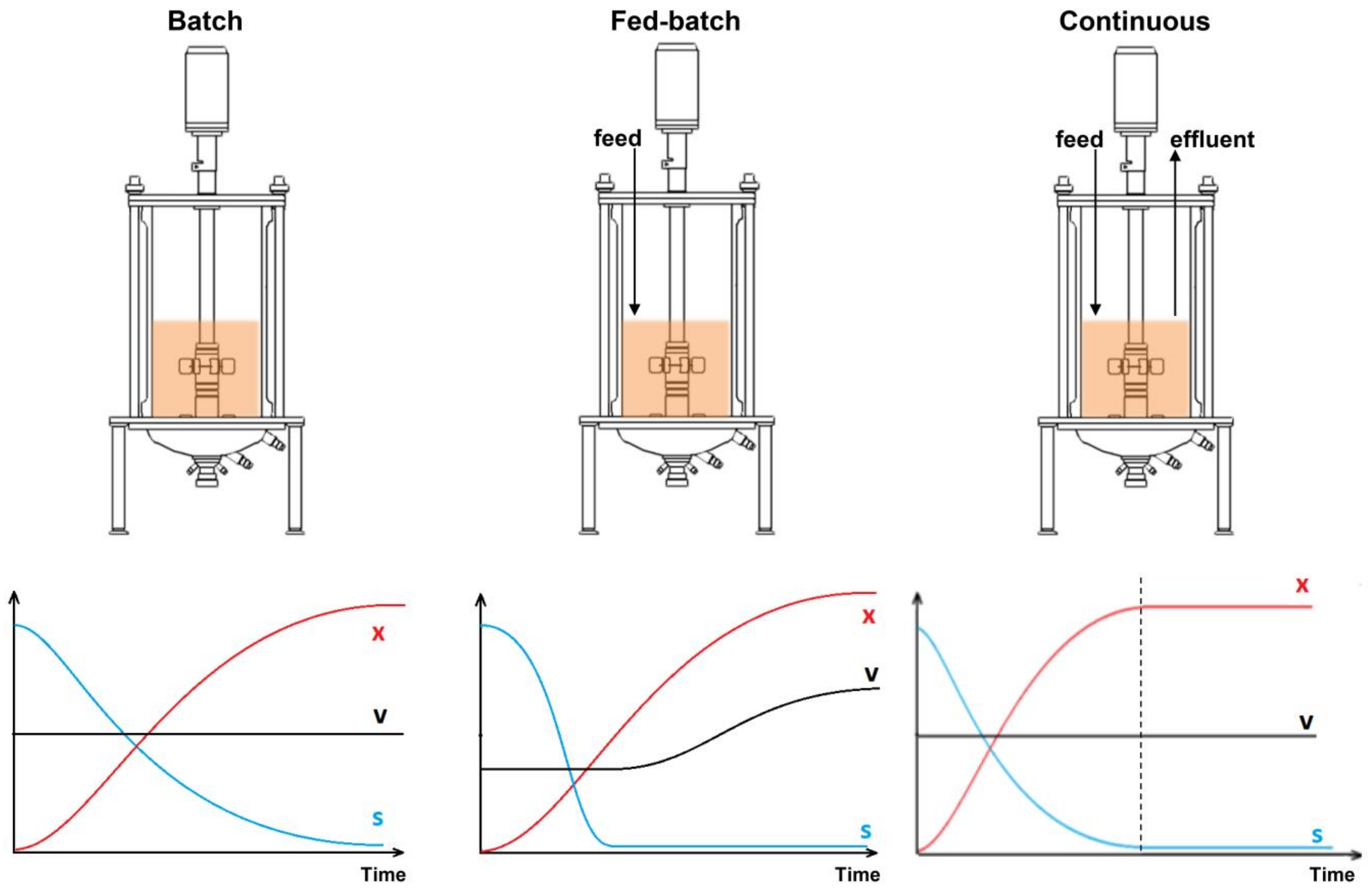

a batch, fed-batch or continuous bioprocess. In batch fermentation, microorganisms are inoculated to. a fixed volume of medium in a fermentor. With microbial growth, the nutrients are gradually consumed and by-products accumulate. Therefore the culture environment is continuously changing. The broth is removed at the end of the run.

Cultures of Biotechnological Importance in

Continuous Culture Definition. Continuous culture is a continuous process where nutrients are continually added to the bioreactor and the culture broth (containing cells and metabolites) is removed at the same time. The volume of the culture broth is constant due to a constant feed-in and feed-out rate (i.e consumed nutrients are replaced and.

Batch culture cultivation Download Scientific Diagram

In batch culture cells grow in a finite volume of liquid medium and are usually maintained in conical flasks on orbital shakers at a speed of 80-120 rpm. There are many types of batch culture: slowly rotating culture, shake culture, spinning culture, and stirred culture.. Diagram illustrating factors influencing growth and stasis at the.

The Difference Between Batch, Fedbatch and Continuous Processes Blog

Batch Culture or Batch Fermentation: A batch fermentation is regarded as a closed system. The sterile nutrient culture medium in the bioreactor is inoculated with microorganisms. The incubation is carried out under optimal physiological conditions (pH, temperature, O 2 supply, agitation etc.).

3 The Bacterial Batchculture Growth Curve (axis numbers are... Download Scientific Diagram

Ø Thus in batch fermentation, the large scale production is done as separates 'batches'. Ø Microbes in the batch culture show the following pattern of growth with distinct phases. (1). Log phase: initial phase, no apparent growth of microbes, they adapt to the environmental conditions. (2).

Bioreactor Fedbatch culture Turbidostat Chemical reactor Chemostat, cell culture flask, angle

Overview Feed automation Perfusion The addition of nutrients and removal of by-products to and from the culture medium, respectively will affect the cell density and viability, the bioprocess duration, and as a result, the product titer, yield, and cost.

Continuous Culture In Fermentation Rezfoods Resep Masakan Indonesia

The fed-batch culture ran for. 12 days and reached a peak density of 21 x 106 cells/mL on day 9. Our perfusion culture ran the longest and reached the highest density of all bioprocess modes by day 15. A batch culture takes significantly less run time than a fed-batch or perfusion and is the easiest process to execute.

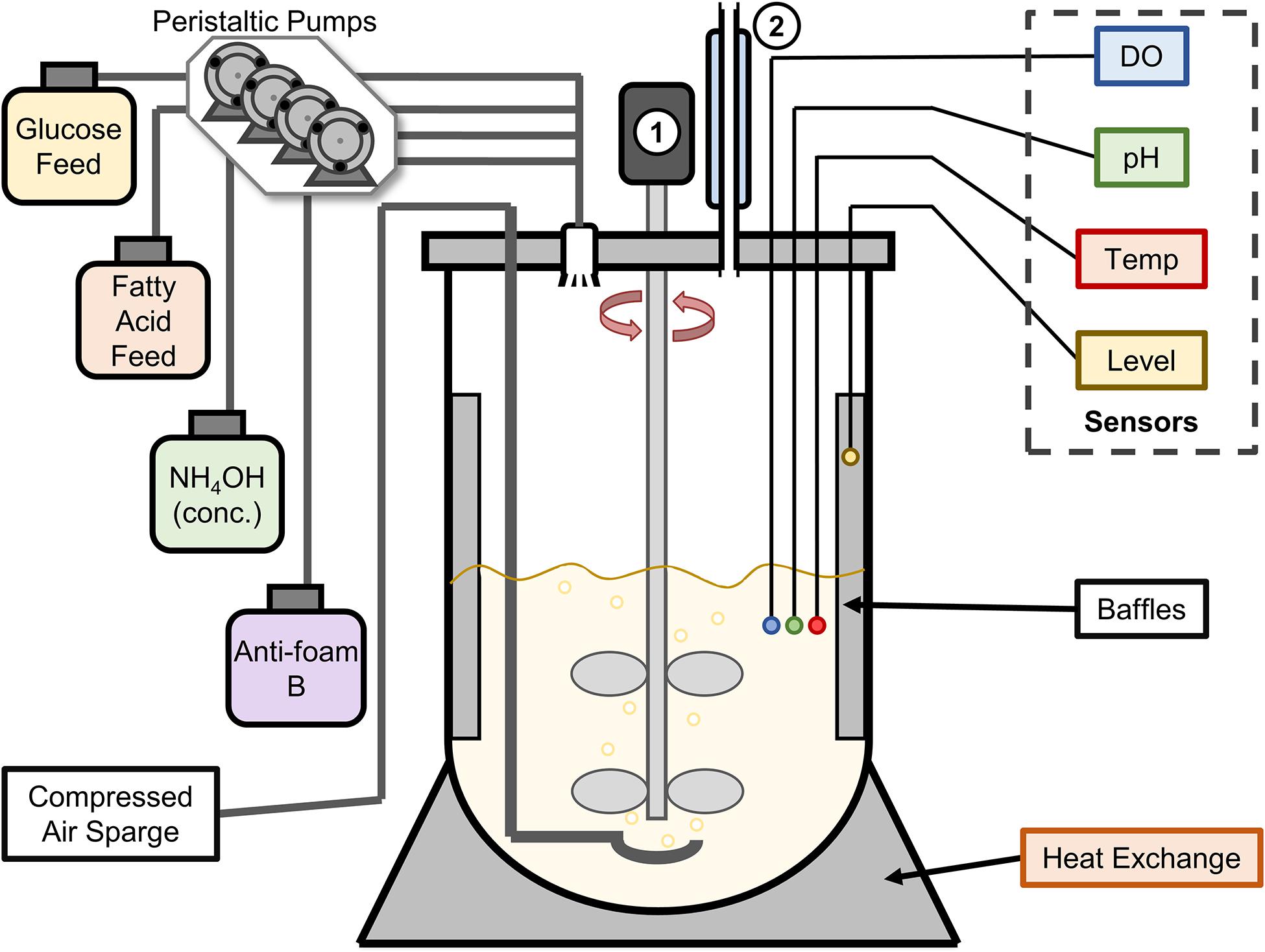

Setup of a concentrated perfusion or fedbatch setup using the... Download Scientific Diagram

4.1 Batch Culture. The cell concentration (or other corresponding parameters) is measured at two points in the exponential phase when the biomass is linearly changed, and the specific growth rate was calculated as follows: μ = (ln D n - ln D n-1)/(t n - t n-1) where D n and D n-1 represent the biomass at t n and t n-1 respectively (usually expressed as cell density, dry weight or.

Schematic diagram of the bioplastics in the batch culture experiment,... Download Scientific

The Choice of Bioreactor Affects Many Aspects of Bioprocessing. Product concentration and purity. Degree of substrate conversion. Yields of cells and products. Capitol cost in a process (>50% total capital expenses) Further Considerations in Choosing a Bioreactor. Biocatalyst. (immobilized or suspended) Separations and purification processes.

Batch Normalization EXPLAINED! YouTube

Batch culture systems are widely applied because of their simplicity and flexibility, allowing to change species and to remedy defects in the system rapidly. Although often considered as the most reliable method, batch culture is not necessarily the most efficient method. Batch cultures are harvested just prior to the initiation of the.

Dhanus Micro Notes Batch, Fed Batch and Continuous Fermentation

Bacterial cultures can be maintained in a state of exponential growth over long periods of time using a system of continuous culture (Figure 4), designed to relieve the conditions that stop exponential growth in batch cultures. Continuous culture, in a device called a chemostat, can be used to maintain a bacterial population at a constant.

Simplification of FedBatch Processes with a SingleFeed Strategy BioProcess

In batch culture, all the medium components are placed in the reactor at the start of cultivation except for atmospheric gases, acid or base for pH control, and antifoaming agents. There is a continuous change in the nutrient concentrations over time, and the system remains unsteady. Fed-Batch Culture Definition

Continuous Culture In Fermentation Rezfoods Resep Masakan Indonesia

Download scientific diagram | Schematic diagram of batch culture. from publication: Metabolic pathways of hydrogen production in fermentative acidogenic microflora | Biohydrogen production from.

Fermentation Free FullText Model Predictive Control—A Stand Out among Competitors for Fed

A typical bacterial growth curve consists of four phases: lag, log, stationary, and death. This bacterial growth curve reflects the events in the bacterial populations when grown in a closed system of microbial culture of fixed volume (i.e., batch culture). This classical growth curve for batch cultures of bacteria was proposed by Buchanan (1918).

Figure 1 from Optimal control of a fedbatch fermentation process using model

A bacteriophage is a type of virus that infects bacteria. It does so by injecting genetic material - either DNA or RNA - which it carries enclosed in an outer protein capsid. To enter a host cell, bacteriophages attach to specific receptors on the surface of bacteria, including lipopolysaccharides, teichoic acids, proteins, or even flagella.

The Difference Between Batch, Fedbatch and Continuous Processes (2022)

Principle Batch Fermentation Process Growth Curve in Batch Culture Advantages Disadvantages Applications Conclusion Batch Fermentation Definition It refers to a technique in which microbial cells grow and multiply to convert substrates into products. Batch fermentation is performed using the stirred tank fermentor.