Rightfirsttime tube bending technology to be highlighted at Farnborough

Free bending forming (FBF) is a flexible forming technology that gained significant attention recently because of its broad applications in critical industries such as the automotive, aerospace, and nuclear industries.

PBT Profile Bending Technology EXPOCLIP 2018 English YouTube

CNC Bending technology. One of the standout features of our CNC bending machine is the infinitely variable CNC-controlled X-Y movement of the bending beams. This remarkable capability empowers the program to precisely dictate the desired bending radius. Advantages. • Suitable for material thicknesses up to 1.5 mm.

Bending Technology LJ Fabricators

Innovative profile bending technology for more than 25 years. Boschert USA is the exclusive North American representative for Swiss company PBT AG, developer and producer of technically advanced profile bending machines and digital control systems.PBT profile bending machines offer exceptional precision and deliver capabilities to satisfy the highest industry requirements for quality and.

Tubebending technology deployed for aerospace applications Engineer Live

The technology can increase bend angle consistency, decrease tooling wear and galling, and minimize part marking. For soft materials that are especially prone to marking or scratching, a Delrin® insert can be installed on one or both lobes of the rotary bender's rocker, or the entire rocker can even be made of Delrin.

Bending in Hungary with cuttingedge technology in outstanding quality.

Tube bending is any metal forming processes used to permanently form pipes or tubing. Tube bending may be form-bound or use freeform-bending procedures, and it may use heat supported or cold forming procedures. Form bound bending procedures like "press bending" or "rotary draw bending" are used to form the work piece into the shape of a die.

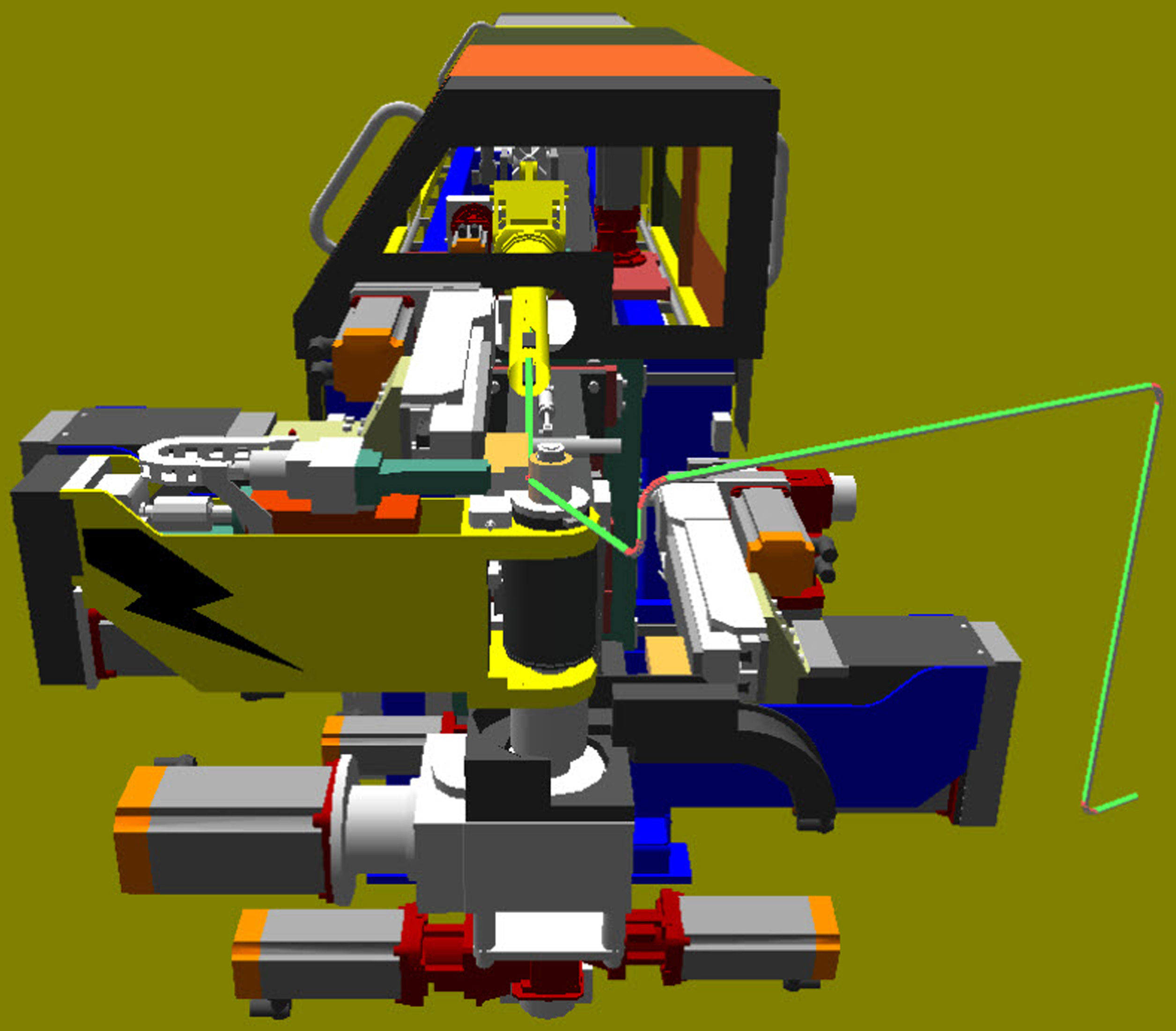

Advanced tube bending technology helps British Airways maintain latest

In recent years, three-dimensional (3D) free bending forming (3D-FBF) technology has been a remarkable technical innovation in metal forming. It is a flexible bending forming technology based on the die trajectory control, as depicted in Fig. 7.1.It has unparalleled technical advantages in forming essential components such as complex three-dimensional axis, continuous bending without straight.

Automated sheet metal bending technology WEMO

By these parameters, laser power and laser duration, the bending radius and the bending angle can be controlled precisely. Fig. 2: Left: Scheme of a bending set-up to perform a 90° shape with different bending radii according to the width of the heat zones b1 and b2, from [2]; right: simulation of bending process, colored is the temperature field.

unison tube bending technology Engineer Live

Bending Technologies specializes in custom tube bending with either single or multiple axes resulting in repeatable, precision parts. We offer a complete approach to bending projects that includes extensive industry knowledge, highly skilled technicians and quality control for the most demanding spe

Induction Bending Technology AWS Schäfer The Pipe Technologists

One is a tube bender technician working for an aircraft parts manufacturer. He's well-versed in bending technology and knows the combinations of tubing alloys, tooling sets, lubricants, and bender settings that result in tight-radius, repeatable bends. The other owns a pickup truck, and he's changing the spark plugs.

Bending technology at Kersten Europe 3D contour cutting YouTube

It is noted that the NC tube bending has become the primary technology for realizing the accurate and efficient tube bending [77,83,91] (shown in Fig. 14). Regarding the above trends in tube bending, the challenges needed to be urgently solved are summari- zed as below: 1) The efficient and precise tube bending depends on the knowledge about.

The most skilled mechanic &most powerful metal bending machineModern

The bend angle refers to the complementary angle of bend. So if a tube is bent to "45 degrees," that's 45 degrees complementary, or a 135-degree included bend angle (see Figure 2 ). The distance between bends (DBB) is just what it says.

HAEUSLER VRM 4Roll Plate Bending Machine FST Fabrication Solutions

IAC Corp. agreed to sell its Mosaic Group suite of mobile-phone apps and intellectual property to Italian technology company Bending Spoons SpA, according to an internal statement reviewed by Bloomberg News. The deal includes Mosaic's suite of apps, such as ones that help users edit PDF documents, and the company's intellectual property and.

Plastic Bending and Forming EhrenHaus Industries, Inc.

1:46. IAC Corp. agreed to sell its Mosaic Group suite of mobile-phone apps and intellectual property to Italian technology company Bending Spoons SpA, according to an internal statement reviewed.

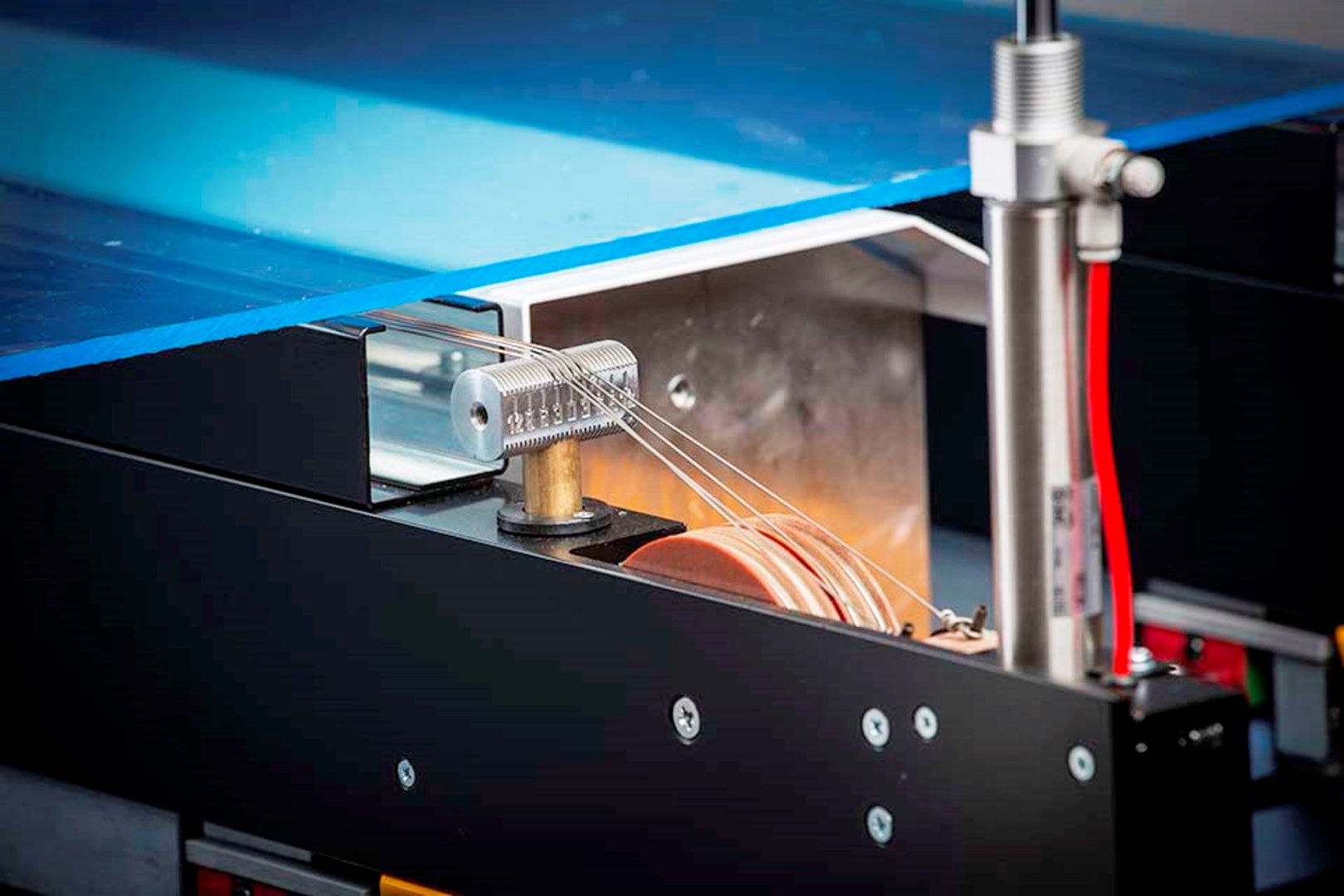

Automated Sheet Metal Bending Technology

In order to assess the longevity of foldable electronics, folding or bending tests on model systems need to be performed. However, not all bending tests are created equal in that different configurations lead to different amounts of mechanical damage and thus different electrical responses. Two 90° bending instruments were compared using two model metallic thin film systems on polyimide to.

Induction Bending Technology AWS Schäfer The Pipe Technologists

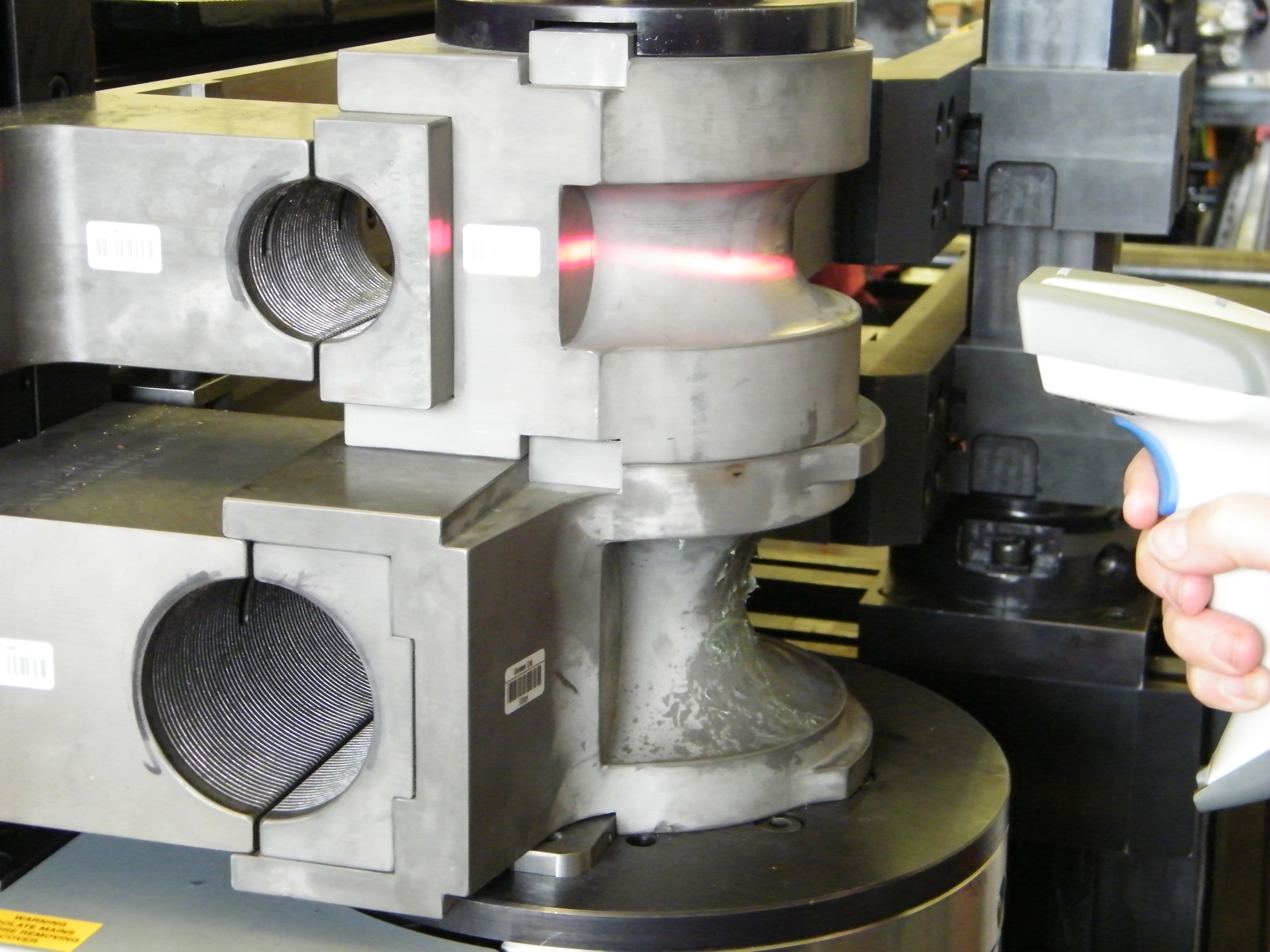

[email protected]. 3-D graphic simulation bar code scanning bending line CNC press brake metal bending press brake sheet metal bending smart technology. With the introduction of innovative machine technologies into modern CNC press brakes, tasks have become simpler and less time consuming and overall productivity has increased.

HAEUSLER RBM Tube Bending Machine / RWM Tube Coil Bending Machine FST

Besides this temperature-based classification of tube bending processes, the different types of tube bending can also be defined based on the technology used. Here is a brief overview of these different types: Press bending: Press bending is one of the simplest bending processes. In press bending, two dies that are inclined at the required bend.